Understanding Overhead Conveyors

Overhead conveyors are an efficient and versatile material handling solution that operates above ground level, freeing up valuable floor space. They consist of a series of trolleys connected to a continuous loop of chains, which are suspended from the ceiling or other overhead structures. These conveyors are widely used in industries where the movement of goods, products, or materials through different stages of production or assembly is essential. Their unique design allows for efficient transport, even in environments where floor space is limited.

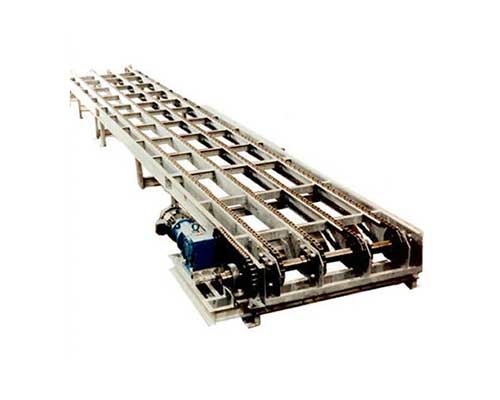

Key Components of an Overhead Conveyor System:

Track: A rigid or flexible path along which the conveyor chain or belt moves. It guides the movement of trolleys or carriers.

Chain: The conveyor's driving force, which connects the trolleys and allows them to move along the track.

Trolleys/Carriers: The components that hold the products being transported. They are connected to the chain and move along the track.

Drive Unit: Provides the necessary power to move the chain and trolleys along the conveyor system.

Support Structure: The framework that holds the entire system in place, typically attached to the ceiling or overhead beams.

Applications of Overhead Conveyors

Overhead conveyors are widely used in industries such as automotive, manufacturing, packaging, food processing, textiles, and warehousing. Their ability to transport materials over long distances without occupying floor space makes them a go-to solution for many businesses.

Common Applications:

Assembly Lines: Overhead conveyors are commonly used in automotive and manufacturing industries for transporting components along production lines. This helps streamline the assembly process and ensures efficient workflow.

Paint Shops: In industries such as automotive and metal fabrication, overhead conveyors are used in paint shops to move products through different stages of painting and drying. The suspended design prevents contamination and optimizes space usage.

Warehousing and Distribution: Overhead conveyors are often used in large warehouses and distribution centers for moving goods from one area to another. This helps improve the overall efficiency of inventory management and order fulfillment processes.

Food Processing: In food processing plants, overhead conveyors are used to transport raw materials, packaging, and finished products through various stages of production, ensuring hygiene and cleanliness.

Textiles: The textile industry utilizes overhead conveyors to move rolls of fabric or garments between production stages, reducing manual handling and increasing productivity.

Benefits of Overhead Conveyors

Overhead conveyors offer several advantages that make them a popular choice across various industries. Here are some of the key benefits:

Space-Saving Solution:

One of the primary benefits of overhead conveyors is their ability to maximize floor space. By operating above ground level, they free up valuable space that can be used for other purposes, such as storage, machinery, or personnel movement. This is particularly important in industries with limited floor area.

Increased Efficiency:

Overhead conveyors are designed to streamline material handling processes, reducing the need for manual labor and ensuring a smooth flow of goods. This leads to faster production cycles, reduced downtime, and increased overall efficiency in the workplace.

Versatility:

These conveyor systems can be customized to suit a wide range of industries and applications. Whether it’s transporting heavy automotive parts or delicate food products, overhead conveyors can be adapted to meet specific needs.

Cost-Effective:

While the initial investment in overhead conveyors may be higher than traditional floor-based conveyors, the long-term cost savings are significant. With reduced labor costs, increased productivity, and minimal maintenance requirements, overhead conveyors offer a high return on investment.

Enhanced Safety:

By removing materials from the ground, overhead conveyors reduce the risk of accidents caused by tripping or collisions with floor-based equipment. This creates a safer working environment for employees.

Environmental Benefits:

Overhead conveyors help reduce energy consumption by minimizing the need for forklifts and other powered equipment. This leads to lower carbon emissions and a more environmentally friendly production process.

Why Choose Perfection Engineering Corporation?

Perfection Engineering Corporation stands out in the overhead conveyor manufacturing industry for several reasons. Here’s why businesses trust them for their material handling solutions:

High-Quality Products:

The company is known for manufacturing overhead conveyors that are durable, reliable, and built to last. Their products undergo rigorous quality checks to ensure they meet industry standards and deliver optimal performance.

Custom Solutions:

Perfection Engineering Corporation offers customized conveyor solutions tailored to the specific needs of each client. Whether it’s a unique production layout or special material handling requirements, they work closely with clients to design the perfect system.

Experienced Team:

With years of experience in the industry, the company’s team of engineers and technicians has the expertise to handle even the most complex projects. Their technical knowledge ensures that every conveyor system is designed and installed with precision.

After-Sales Support:

Perfection Engineering Corporation provides excellent after-sales support, including installation, maintenance, and troubleshooting services. Their commitment to customer satisfaction ensures that clients can rely on their conveyor systems for years to come.

Competitive Pricing:

Despite offering high-quality products and services, the company maintains competitive pricing. This allows businesses of all sizes to invest in top-tier material handling solutions without breaking the bank.